WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Scrap aluminum plastic medical blister separation machine of DOING is also called aluminum plastic recycling machine, which is a processing line to separate pure aluminum and plastic from waste medical blister.

Scrap aluminum plastic medical blister separation machine

Scrap aluminum plastic medical blister separation machine

The working process includes crushing, grinding, sieving, electrostatic separation and dust collecting. Scrap aluminum plastic medical blister separation machine adopts dry physical separation method, uses no fire, water, or chemical solution, which means it is an environmental friendly machinery.

Here is a 3D working video of scrap aluminum plastic medical blister separation machine. Hope it can help you have a good understanding of the working process.

Scrap aluminum plastic medical blister separation machine is used to process waste aluminum plastic medical blister. Aluminum plastic medical blister is the waste materials, defective packing, leftover materials produced from pharmaceutical factory or medical institutions. It has single sided aluminum medical blister and two-sided aluminum medical blister. The aluminum content of single sided aluminum medical blister is generally about 10-12% and higher content in two-sided aluminum medical blister. As for the plastic in medical blister, it is generally is PVC, or PP material.

Scrap aluminum plastic medical blister separation machine

Scrap aluminum plastic medical blister separation machine

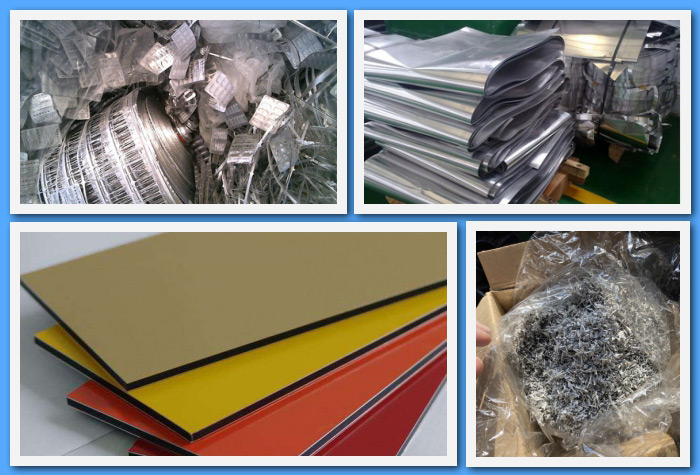

Actually, scrap aluminum plastic medical blister separation machine can not only process scrap medical blister, it can also process aluminum plastic composite panel (ACP), aluminum plastic, aluminum plastic shaving materials, etc.

Final products application

Final products application

The final products of scrap aluminum plastic medical blister separation machine are aluminum and plastic. The aluminum can be used for making aerated aluminum paste, fireworks powder, bubble brick, etc. The plastic can be made into plastic sheet products, tray or pelleting into other PVC, PP products.

[ Recommended reading: Can I recycle medicine blister packs for profit? ]

| Capacity (Kg/h) | Overall Dimension | Power (Kw) | Weight (Kg) | Recovery Rate |

| 200-300kg/h | 8500*4500*4200mm | 94kw | 6800kg | ≥99% |

| 300-400kg/h | 9500*5000*4200mm | 135kw | 7600kg | |

| 500-600kg/h | 11500*6500*4200mm | 316kw | 12600kg | |

| 800-1000kg/h | 16000*9000*4200mm | 483kw | 13500kg |

Scrap aluminum plastic separation machine feature

Scrap aluminum plastic separation machine feature

1. Simple in structure, steady running.

2. Good quality, long use life.

3. PLC control system, convenient in maintenance and operation.

4. High separating rate, no plastics in the aluminum, and no aluminum in plastics.