WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Copper wire shredder and granulation system is an automated assembly line, which is used to process waste cable wires to get copper and plastic.

Various waste cable wires

Various waste cable wires

Copper wire shredder and granulation system can not only process copper wires such as telephone wires, earphone wires, household square wires, industrial cables, etc., but also aluminum wires, copper-aluminum composite wires, etc.

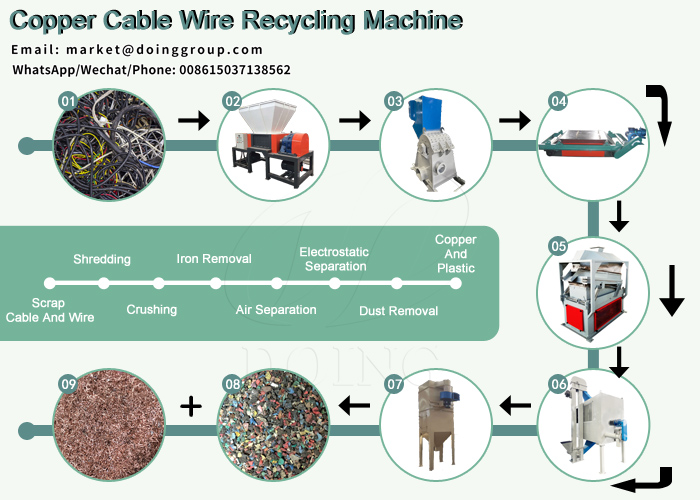

Working process of copper wire shredder and granulation system

Working process of copper wire shredder and granulation system

1. Shredding - Use double-shaft shredder to shredthe waste cable wires into 2-5cm;

2. Magnetic separation - Use magnetic separator to remove iron firstly;

3. Crushing - Use crusher to crush waste cable wires into small particles;

4. Air separation - Use air separator to separate copper/aluminum from plastic according to their different gravity;

5. Electrostatic separation - Use electrostatic separator to separate the copper/aluminum from the separated plastic according to the different conductivity of metal and non-metal;

6. Dust removal - Use pulse removal and cyclone removal system to collect the dust.

Final products and application

Final products and application

Copper: It can be sold in the metal trading market directly, or you can make new products, like copper ingots, copper Electrolysis, and then sell.

Plastic: As for plastic, it can be sold directly as well. Or you can pellet the plastic into other products, like wire cover, tray, blister sheet, etc.

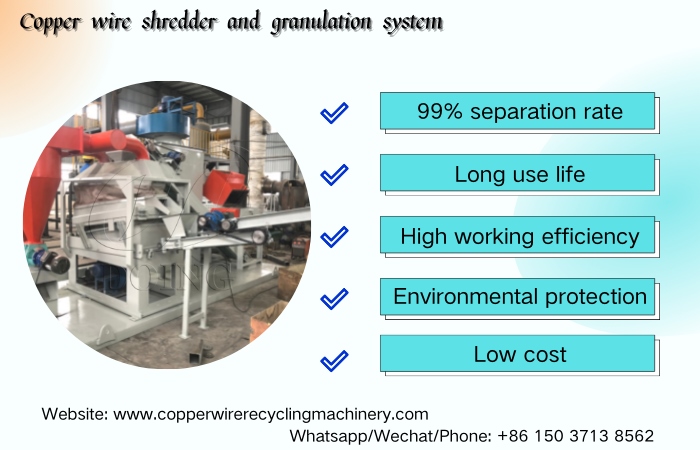

Advantages of copper wire shredder and granulation system

Advantages of copper wire shredder and granulation system

1. Long use life: Adopt H13 and SKD-11 materials, which are more wear-resistant and strong resistance.

2. High separation rate: Adopt air separation and electrostatic separation, which can make the separation rate reach to 99%.

3. Environmental protection: Adopt dry type physical separation method and double dust removal system, which has no pollution to environment.

4. Low cost: Adopt PLC control system and compact structure, which saves labor, electricity, land cost.

5. High working efficiency: Processing capacity ranges from 100kg/h to 2T/H, which can be customized accordingly.

If you are interested in it, and want to know more information about copper wire shredder and granulation system, please contact us, and we will give you our best support.