1.Aluminum recycling machine brief introduction

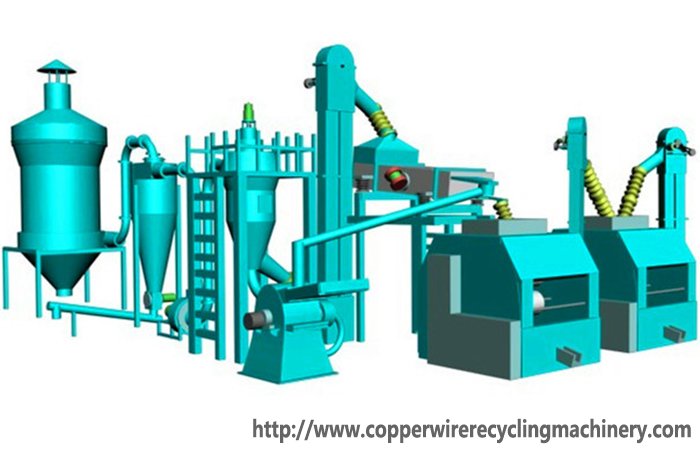

Aluminum recycling machine

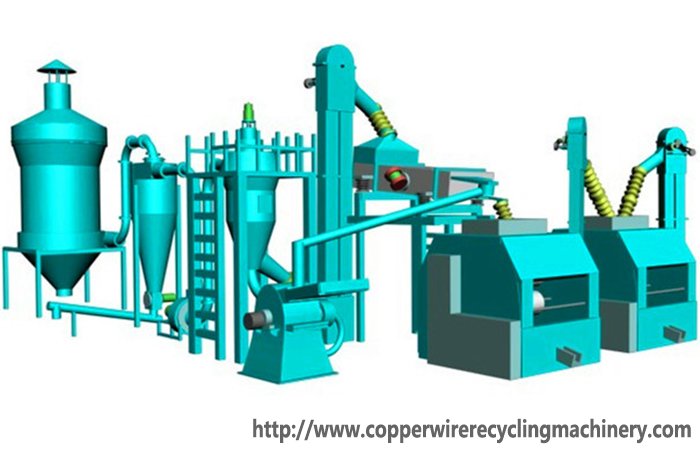

Aluminum recycling machine is a high efficiency energy-saving product which is developed by our factory based on absorbing separation technology at home and abroad .With years of experimentation and theoretical analysis ,this machine can reach the best separation effect .The ratio of impurities after separation will be less than 1% ,i.e . the separation efficiency is up to 99%.

2.Aluminum recycling machine advantage

Aluminum recycling machine

Aluminum recycling machine

With this waste aluminum recycling machine (separator), the aluminum and plastic can be completely separated for comprehensive utilization and to achieve a higher economic benefit without dust and secondary pollution.

This equipment uses our self-owned triple dust collecting unit (triple dust collector), including three stages, cyclone, cloth-bag and air cleaner dust collectors, which can effectively solve the dust pollution problems.

The aluminum recycling machine is characterized by little noise, great output and high innovation. After separation, the original quality of aluminum remains and plastic is recovered to produce great economic benefit.

This waste aluminum plastic recycling machine(separator) uses high pressure electrostatic separation technology to achieve a higher metal recovery (above 98%).

3. Aluminum recycling machine Application

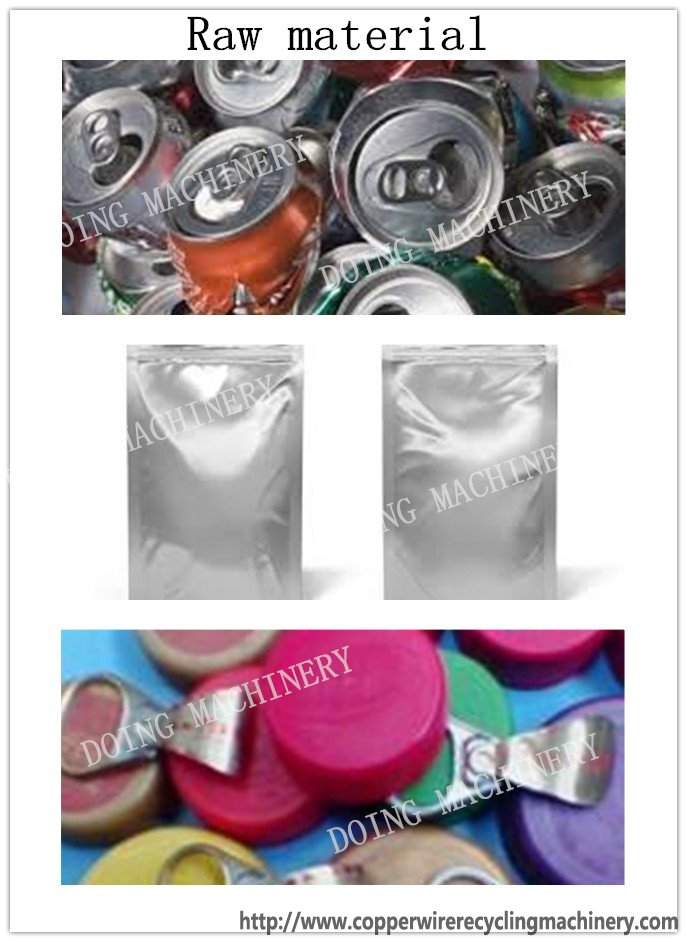

This aluminium recycling machine can be used to recycle hard aluminium plastic composite material, like aluminium plastic composite panel (ACP), aluminium plastic composite pipe, blister pack for drug etc.

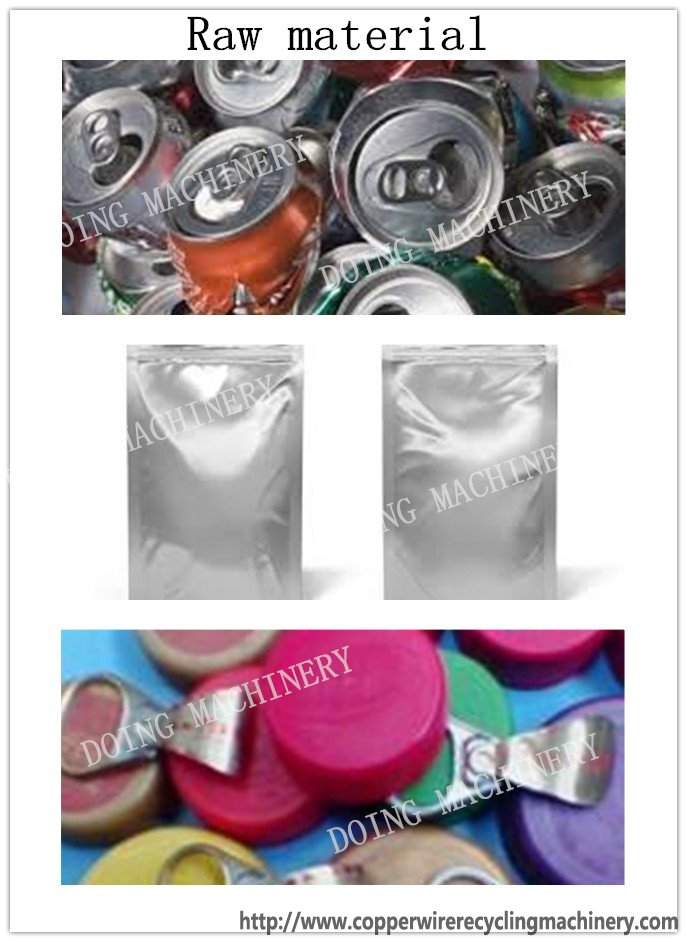

Aluminum recycling machine Application to this raw material

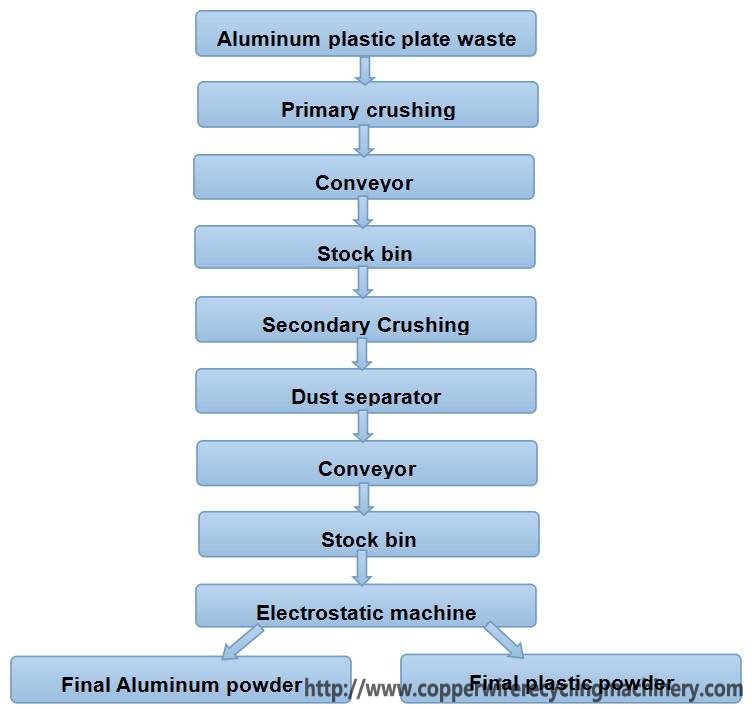

4. Aluminium recycling machine working principle

This aluminum recycling machine uses advanced physical recycling technology. Its products line, like aluminum-plastic separator, crusher and high pressure electrostatic separator, is of high innovation and advanced and reasonable technological line..

5. Aluminum recycling machine technical parameter

|

Model |

Voltage |

Power |

Capacity |

Dimension |

Weight |

|

DYLS-400 |

380V |

22.45 kw |

150-200kg/H |

2700*1900*2300(mm) |

1200kg |

|

DYLS-600 |

380V |

36 kw |

300-400kg/H |

3500*1900*2700(mm) |

3000kg |

|

DYLS-800 |

380V |

75 kw |

500-600kg/H |

5500*4500*3300(mm) |

8000k |